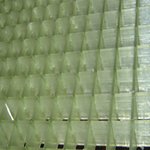

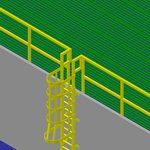

Molded Grating

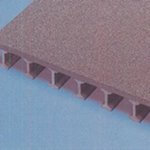

MinGrate® molded fiberglass grating is a one-piece, reinforced FRP grating, available in various meshes and manufactured by interweaving continuous, thoroughly wetted, fiberglass strand with thermosetting resin systems. Standard panels are available in four resin systems, Isophthalic Polyester (I), Vinyl Ester (V), Orthophthalic (O), Phenolic (P).

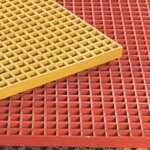

MinGrate® molded grating is widely used for floor systems, walkways, work platforms, stairs, ramps, trench covers & catwalks and has been successfully used in many industries – including food processing, beverage, chemical processing, water & wastewater treatment, metal finishing, pulp/paper, transportation, pharmaceutical, textile, oil / gas & mining / smelting, refining.

| Features and Advantages | |

| CORROSION RESISTANCE | For highly aggressive environments, MinGrate vinyl-ester resin system (VEFR) is recommended. Unlike metal grating, it does not rust and never needs painting. Combined with superior corrosion resistance, mean that MinGrate is a long-lasting, maintenance-free product. |

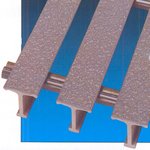

| SAFETY | The top surface of MinGrate Molded Grating is meniscus (concave) to provide outstanding skid resistant, with optional grit top surface to have betterment in anti-skid, especially for wet environment. |

| FIRE RETARDANCY | MinGrate Molded Grating is available in eight standard resin systems, in which six of them meet the Class 1 flame spread rating of 25 or less, per ASTM E-84. |

| LOW MAINTENANCE | Never rusts – never needs painting. And it’s very easy to clean |

| EASE OF FABRICATION | It is easy to cut with ordinary hand tools, using a masonry, carbide tip blade or diamond edge. (it is similar to working with wood or plastic.) |